We Build Machines

Design and Engineering

Leverage decades worth of experience in mechanical, electrical, controls, and robotics to develop a custom machine or automation system design.

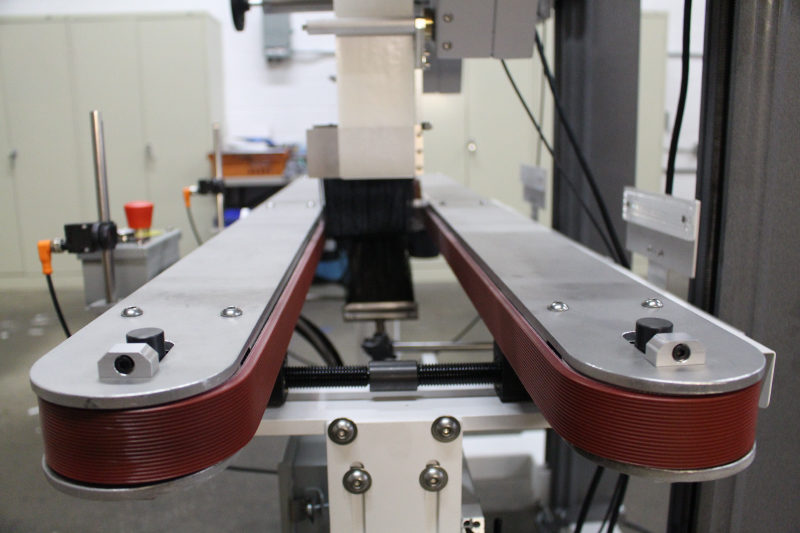

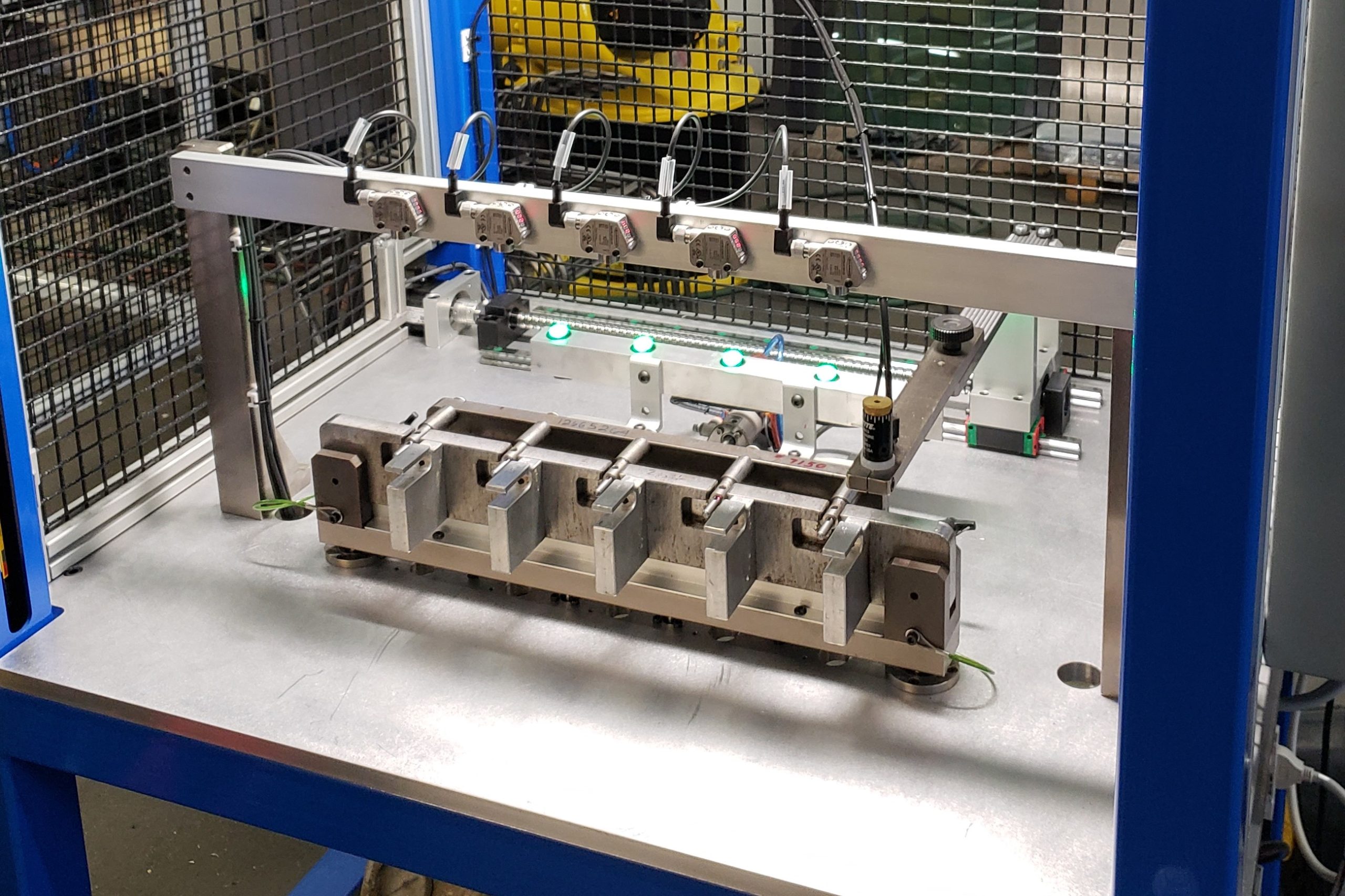

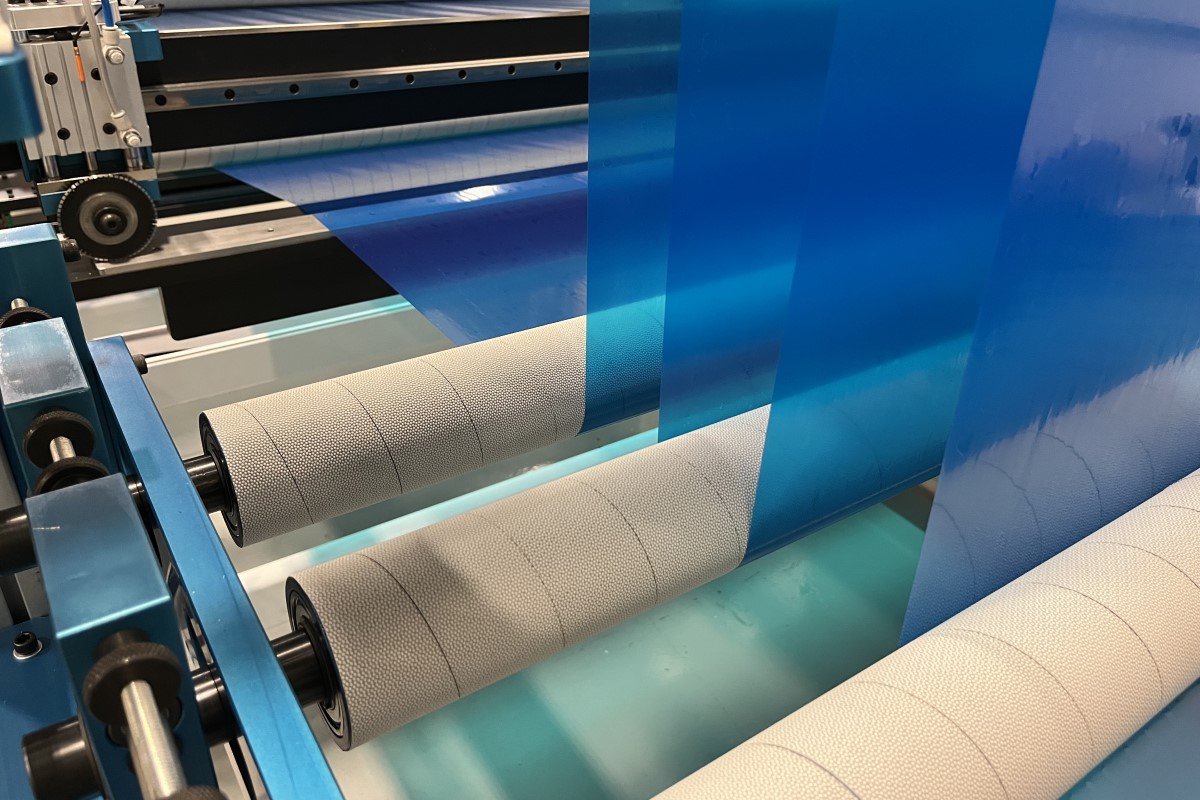

Fabrication and Build

We're not just idea people. Our in-house fabrication and machine building services can take your idea and turn it into a real world working machine.

Commissioning and Deployment

Trust our installation services to ensure your machine is fully commissioned, programmed, and functional to all requirements.

INDUSTRIES SERVED

PORTFOLIO

OUR EXPERTISE

Mechanical Design

Prodesign prides itself on developing custom and innovative mechanical solutions that are reliable, effective, and well within budget. Pneumatic, electromechanical, or hydraulic - if your project needs it, we have the skills at your service.

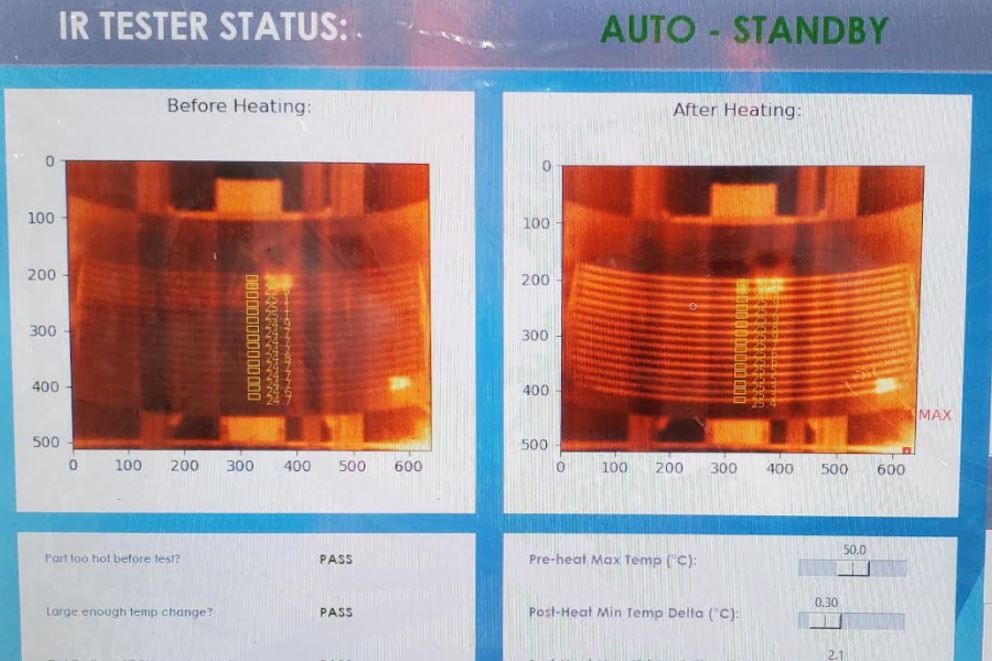

Electrical and Controls Design

Panel design, sensors, wiring, machine vision, and PLC programming. We have the controls experience to bring your mechanical system to life.

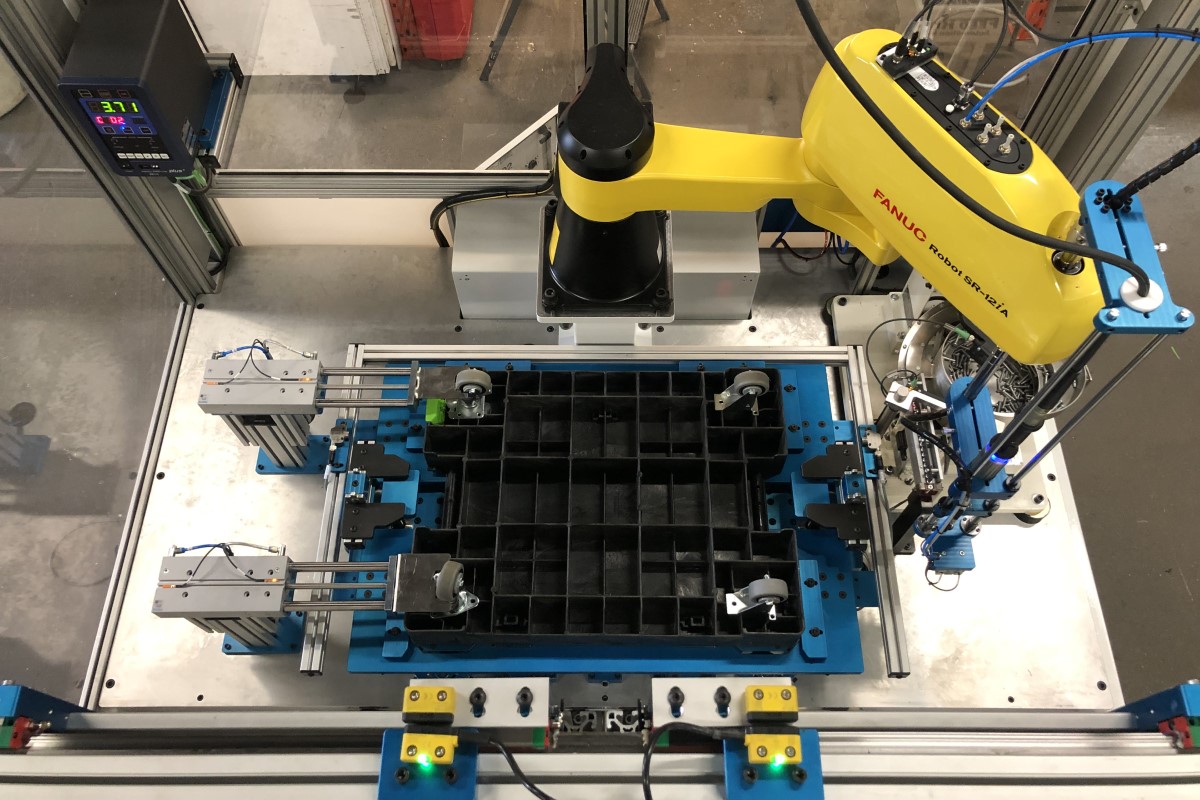

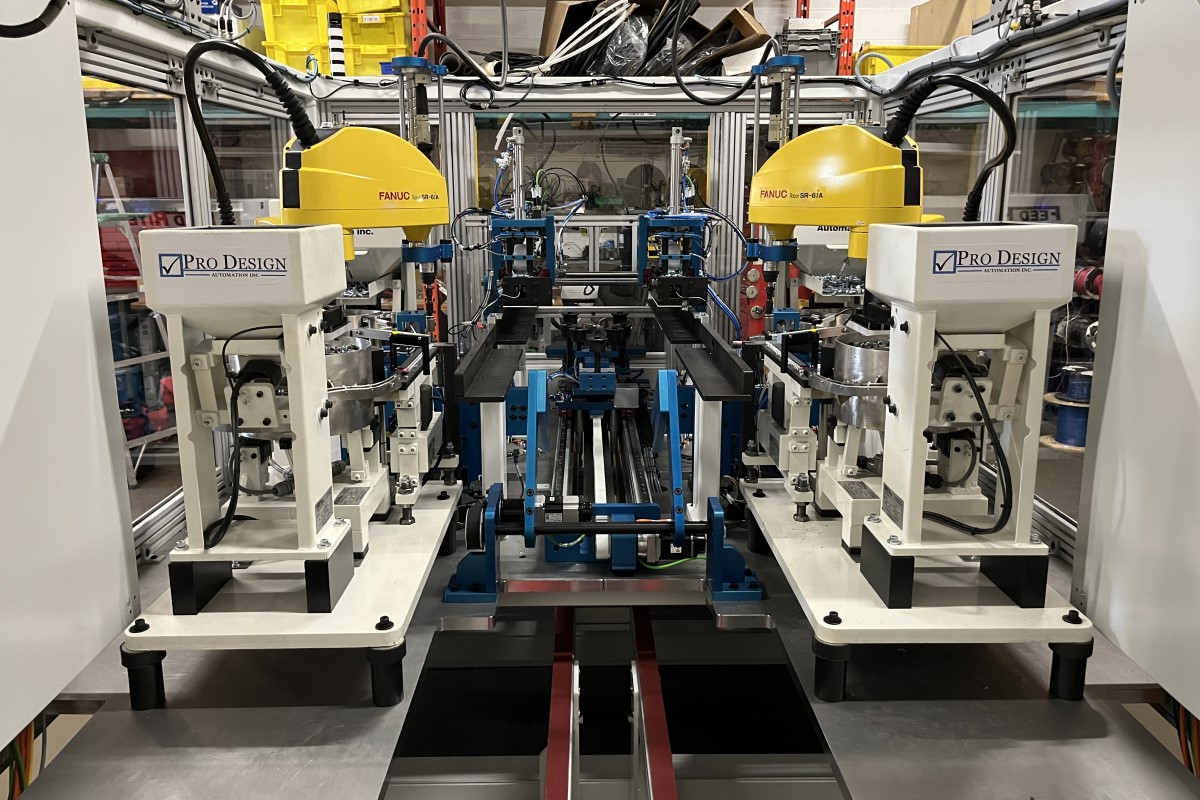

Robot and PLC Integration

Integration and programming services are available with all major robot brands.

Fabrication, Assembly, and Commissioning

Our in-house fabrication and assembly services can bring your idea to a working final product. Milling, Turning, CNC, surface grinding, wiring, and assembly are all done in-house for fast turn around production times.

WORKING WITH Prodesign...

Prodesign is your partner for any stage of your project. Whether you’re looking to retrofit an existing machine, or you need a full customized turn-key solution from scratch, our engineering and fabrication teams are ready to assist in any of the 5 project stages highlighted below:

1. Requirements and Scope Definition

Our team will meet with you and develop a custom concept solution based on your company’s specific requirements. Major mechanisms and components are defined and an estimate on pricing and delivery are provided.

2. Detailed Design

After receiving the go-ahead, our engineers, designers and fabrication specialists work from the agreed upon concept and develop a fully fleshed out solution using the latest CAD tools.

3. Fabrication, Production, and Assembly

Once the detailed design is agreed upon, and the top level approval drawings are given the green light, a full production drawing package is created. Parts and stock material are sourced. Fabrication of custom components is initiated followed by assembly of the solution. Controls programming can also be done in parallel.

4. Commissioning and Testing

If required, ProDesign can accommodate factory acceptance tests. At our location, we will simulate real production environments and conditions to demonstrate the full functionality of the system.

5. Delivery and Installation

Our project managers will coordinate with you to ensure safe and easy transportation of the system to the final delivery point. Our off-site team will be made available to conduct any on-site training and installation if required.

About us

Based just north of Mississauga in Brampton, Ontario (within the Greater Toronto Area), ProDesign Automation has been providing custom automated machinery and industrial solutions for small and mid sized projects since 2007. Originally, ProDesign was established to serve the needs of industry local to the Greater Toronto Area and surrounding regions. Now the ProDesign machine nameplate can be found on machines and installations well beyond the boundaries of the Toronto region with international active machine deployments.

All of our machinery, automation and control panels are made 100% in house. This ensures that we maintain control over build quality and accuracy of our customers projects.

All of our original customers since our launch in 2007 are still active customers today! We take great pride in our track record; every machine that has been ordered from ProDesign Automation has been accepted by the customer and has entered production. We welcome you to join our customer base and look forward to working with you to provide solid machinery solutions and, of course, our great personal service.

READY TO GET STARTED? CONTACT US TO SETUP A CONSULTATION?

Some of our current clients...